Development of a pseudo TPUS probe to improve consistency of patient positioning during MRI.

Eric Pei Ping Pang,

Singapore

PO-1829

Abstract

Development of a pseudo TPUS probe to improve consistency of patient positioning during MRI.

Authors: Eric Pei Ping Pang1, Yong Kang Lim2, Keith Swee Kok Heng2, Chin Hui Tan3, Yufeng, Andy Lin3, Jason Wei Siang Chan1, Gee Keng Low1, Jeffrey Kit Loong Tuan4

1National Cancer Centre Singapore, Division of Radiation Oncology, Singapore, Singapore; 2SingHealth Duke-NUS, Institute for Patient Safety and Quality, Singapore, Singapore; 3National Cancer Centre Singapore, Department of Oncologic Imaging, Singapore, Singapore; 4National Cancer Centre Singapore, Division of Radiation Oncology, Singapore, Singapore

Show Affiliations

Hide Affiliations

Purpose or Objective

Locally, patients undergoing prostate radiotherapy are monitored for prostate displacement using an autoscan 4D transperineal ultrasound (TPUS) probe during treatment. However, the existing TPUS probe and autoscan probe kit (ASPK) are not MRI-compatible. Hence, uncertainties due to variations in patient position and delineation of the prostate gland based on CT/MRI fusion may be introduced during treatment planning. This project aims to develop a MRI-compatible pseudo

TPUS probe and ASPK to reproduce patient position during MRI to facilitate image fusion and prostate gland contouring during treatment

planning.

Material and Methods

The fabricated MRI-safe TPUS probe and ASPK were designed and produced in

components with certain parts required to provide mechanical functions for angulation and height adjustments with similar accuracy of the existing probe used during treatment. Major components were modelled separately for producing parts using MRI-safe materials and assembly. The first prototype was printed as a singular part in both FDM and PolyJet. Selected materials must not introduce any magnetic field interference or contra-indicate MRI procedures (i.e. must not get heated up by magnetic waves). Selected manufacturing process had to consider production of parts that can ensure the rigidity and accuracy of the structure to

withstand pressure on the probe at the transperineal region (i.e. Computerized Numerical Control (CNC) machined

vs 3D printing). CNC process was eventually selected as 3D-printed parts tend to create

material warpage that reduces the accuracy of the design and the material strength required.

Results

Materials that passed both image

test and metal detector test: PVC, PP, ABS, Wood Meranti, Polycarbonate, with Aluminium

Composite failing both image and metal detector test. Acrylonitrile Butadiene Styrene (ABS) was selected as the

MRI-safe material for development of the prototype due to its durability, rigidity, strength, corrosion and

impact-resistant. A test scan was performed on the MRI

scanner and found to be safe and artefact-free for target used cases. (Figure

1). Two rounds of prototyping were conducted to arrive at the final product

(Figure 2).

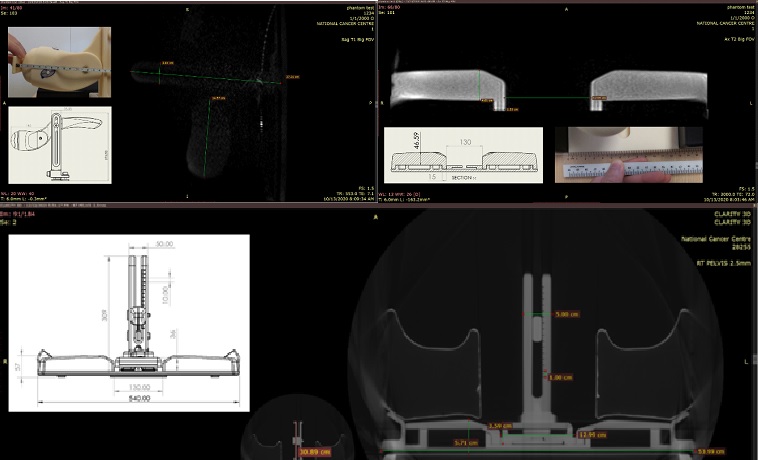

Figure 1: Test scans images

from the MRI Scanner on the final design probe and ASPK setup

(Material passed the image test and dimension accuracy was achieved).

Figure

2: Final CNC machined prototype of the MRI-safe probe and ASPK (with commercial

knee rest).

Conclusion

Final CNC-machined MRI-safe

probe and ASPK was developed for subsequent TPUS prostate patients requiring CT/MRI fusion during radiotherapy treatment

planning. Moving forward, the effectiveness of this gadget on the reproducibility of patient position during MRI to facilitate image fusion for contouring of the prostate gland will be assessed in this novel

clinical workflow for prostate cancer patients. Additionally, the gadget can also be used for patient education to improve compliance during setup.