Radioluminesence imaging for CyberKnife® dosimetry and quality assurance

Antonello Spinelli,

Italy

PO-1525

Abstract

Radioluminesence imaging for CyberKnife® dosimetry and quality assurance

Authors: Antonello Spinelli1, Zahra Shakarami1, Sara Broggi2, Antonella del Vecchio2, Claudio Fiorino2

1San Raffaele Scientific Institute, Experimental Imaging Center, Milan, Italy; 2San Raffaele Scientific Institute, Medical Physics, Milan, Italy

Show Affiliations

Hide Affiliations

Purpose or Objective

To investigate the applicability of

radioluminescence imaging (RLI) as a novel 2D quality assurance (QA) dosimetry

system for CyberKnife®.

Material and Methods

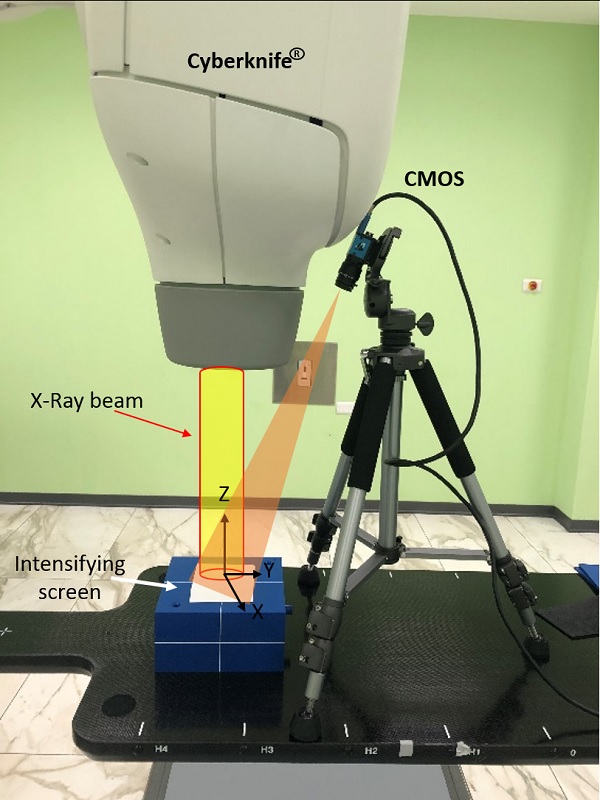

We developed a real time dose measurement system

based on a commercial complementary metal oxide semiconductor (CMOS) camera

facing a radioluminescence screen located at the isocenter (Figure.1). The

radioluminescence light collected by a lens was used to measure 2D dose

distributions. An image transformation procedure, based on two reference

phantoms (square and star), was developed to correct for projective distortion

due to the angle (15 degrees) between the optical and the radiation beam main axis.

Dose profiles were measured for field sizes ranging from 10 mm to 60 mm using

fixed circular and Iris™ collimators and compared against gafchromic film

(GC). The corresponding full width at half maximum (FWHM) was measured using

the RLI and benchmarked against GC film. Small shift of the isocenter position were introduced on purpose to test

the sensitivity of the RLI system to field size variations.

Figure 1: RLI acquisition

setup. The radiation beam (yellow) impinged on

the

scintillation screen, which then emits light collected by the camera (orange).

Results

The FWHM measurements using the RLI system

indicated strong agreement with GC film with maximum absolute difference equal

to 0.131 mm for fixed collimators and 0.049 mm for the Iris (Table.1). A 2D

analysis of RLI with respect to GC film indicated that the differences in the

central region are negligible, while small discrepancies are in the penumbra

region (30%-70%). Changes in field sizes of up to 0.2 mm were detectable by RLI.

Table 1: FWHM (mm) obtained from the RLI line profiles and

compared with the GC films.

| Field Size (mm) | FWHM (mm) |

| Discrepancy |

|

| RLI | GC Film | mm | % |

| X-direction |

|

|

|

|

| Circle 10 | 10.039 | 10.108 | -0.069 | -0.68 |

| Circle 40 | 41.206 | 41.269 | -0.063 | -0.15 |

| Circle 60 | 61.88 | 61.82 | 0.06 | 0.097 |

|

|

|

|

|

| Y-direction |

|

|

|

|

| Circle 10 | 10.714 | 10.753 | -0.039 | -0.36 |

| Circle 40 | 41.148 | 41.259 | -0.111 | -0.26 |

| Circle 60 | 61.984 | 61.853 | 0.131 | 0.211 |

|

|

|

|

|

| Two facing sides |

|

|

|

|

| Iris 10 | 9.78 | 9.80 | -0.02 | -0.2 |

| Iris 40 | 37.052 | 37.095 | -0.043 | -0.11 |

| Iris 60 | 56.817 | 56.866 | -0.049 | -0.086 |

Conclusion

The first application of a novel RLI approach

for CyberKnife® dosimetry was presented and tested. Results are

in agreement with GC film measurements. The sensitivity, sub-mm spatial resolution,

simple setup, immediate availability of the data and full automation of the

readout and processing, make this optical system as an

useful and effective tool for robotic radiosurgery quality assurance.

Key words: Radioluminescence imaging, CyberKnife, Quality assurance.