To

generate the patient specific applicator, a CT scan (Somatom definition edge, Siemens Healthcare GmbH, Germany)

was acquired of the H&N phantom in supine position. Delineation of a CTV in the region of the left nose wing and cheek was

performed by a physician. Next, a 3D mesh of the body and CTV were exported from

Eclipse (Varian, USA) using scripting. Subsequent design of the applicator was done

in TriMatic (Materialise, Belgium). Within a 10 mm thick bolus, nine channels

(2.2 mm diameter) were designed 5 mm from the patient surface and spaced 1 cm

apart from each other. The direction, location and number of

channels were manually optimized for target coverage and minimal local

curvature to assure proper passage of the BT-source. The applicator was printed

on a Raise3D N2+ 3D printer (Raise3D, Netherlands) using PLA (ICE filaments,

Belgium) with 100% infill and 2 shells.

For

treatment planning, a second CT was acquired of the applicator positioned on

the phantom, with 5f BT catheters and radio-opaque markers in place. Next, the dosimetric

planning was performed in Oncentra Brachy 4.5.2 (Elekta, Netherlands) with a 7

Gy prescription at 5 mm under the body surface.

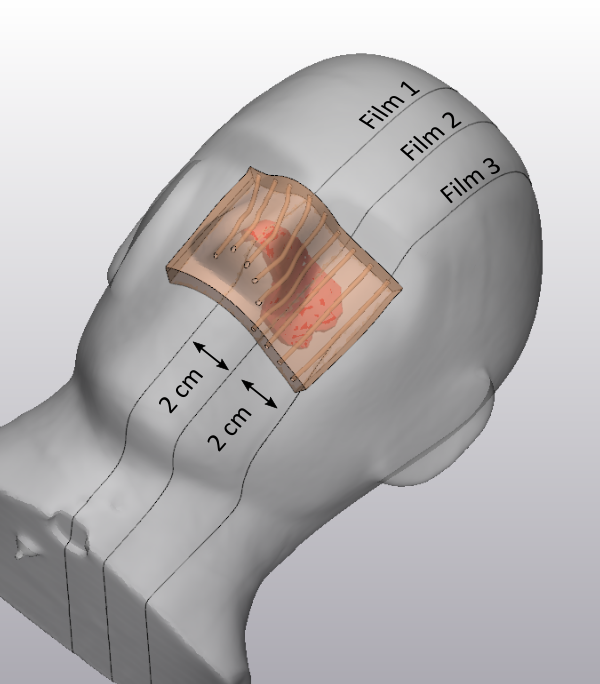

The treatment

was delivered with an Ir-192 Flexitron afterloader (Elekta, Netherlands) with

laser cut EBT3 films positioned in the three sagittal planes of the phantom. The films were

scanned and converted to dose using a calibration procedure for page-sized

films and triple channel correction methodology1.