Validation of daily quality assurance of output, flatness and symmetry of an MR linear accelerator

Hans Lynggaard Riis,

Denmark

PO-1631

Abstract

Validation of daily quality assurance of output, flatness and symmetry of an MR linear accelerator

Authors: Hans Lynggaard Riis1,2, Adriaan Fietje3, Kenni Højsgaard Engstrøm1, Uffe Bernchou4,5, Carsten Brink1,5, Vibeke Nordmark Hansen1, Anders Smedegaard Bertelsen4

1Odense University Hospital, Department of Oncology, Odense, Denmark; 2University of Southern Denmark (SDU), Department of Clinical Research, Odense, Denmark; 3Elekta Instrument AB, Service, Stockholm, Sweden; 4Odense University Hospital, Department of Oncology, Odense , Denmark; 5University of Southern Denmark (SDU), Department of Clinical Research, Odense , Denmark

Show Affiliations

Hide Affiliations

Material and Methods

A PTW 1D water phantom with two PTW Farmer chambers

type T30006 located in a water phantom on the beam axis at depth 10 and 20 cm. The

detector at depth 10 cm was located at the isocentre of the linac. An

electrical pulse counter was connected to the linac. The gantry was at 90

degree, the field size was 22×10 cm, and 100 MU was delivered in each beam. The

CCPS value was varied in steps of 5 V in the linac control software. For each MVIC

exposure the electrometer readings, and pulse countings were registered. The scaling

factors and intensities of the MVIC images were extracted to calculate the

output, flatness and symmetry parameters of the beam.

Results

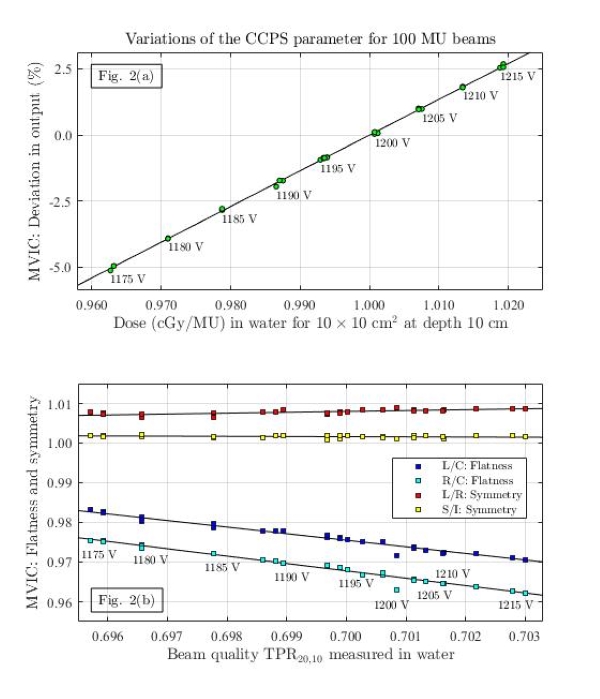

In Fig. 2(a) the deviation in output is shown as

function of reference field calibration for different settings of the CCPS. A

change of 5 V in CCPS results in approximately 1% decrease in output. This is

slightly less than what was observed in Fig. 1 which was around 1.5%. The magnetron feedback software was disabled in the

measurements shown in Fig. 2 while it was enabled in Fig. 1. Also, an energy

change might be the explanation of the small difference in output compared in

Fig. 1 and 2(a) for a 5 V change of CCPS. In Fig. 2(b) the flatness and symmetry

properties of the beam are shown for different settings of the CCPS. The CCPS

value affect the energy which is seen as a change in flatness. The MVIC panel

was able to detect small energy changes. An increase in energy (TPR20,10)

results in a decrease in flatness.

Conclusion

The MVIC panel of the Elekta Unity linac was found

being a valuable, efficient and a reliable tool to detect small changes in output

as well as in energy. It is a strength that the MVIC panel is in fixed position

all time relative to the linac beam thereby reducing setup uncertainties. Therefore,

the MVIC system may detect changes before observed by other external systems

such as water phantoms used for routine QA.